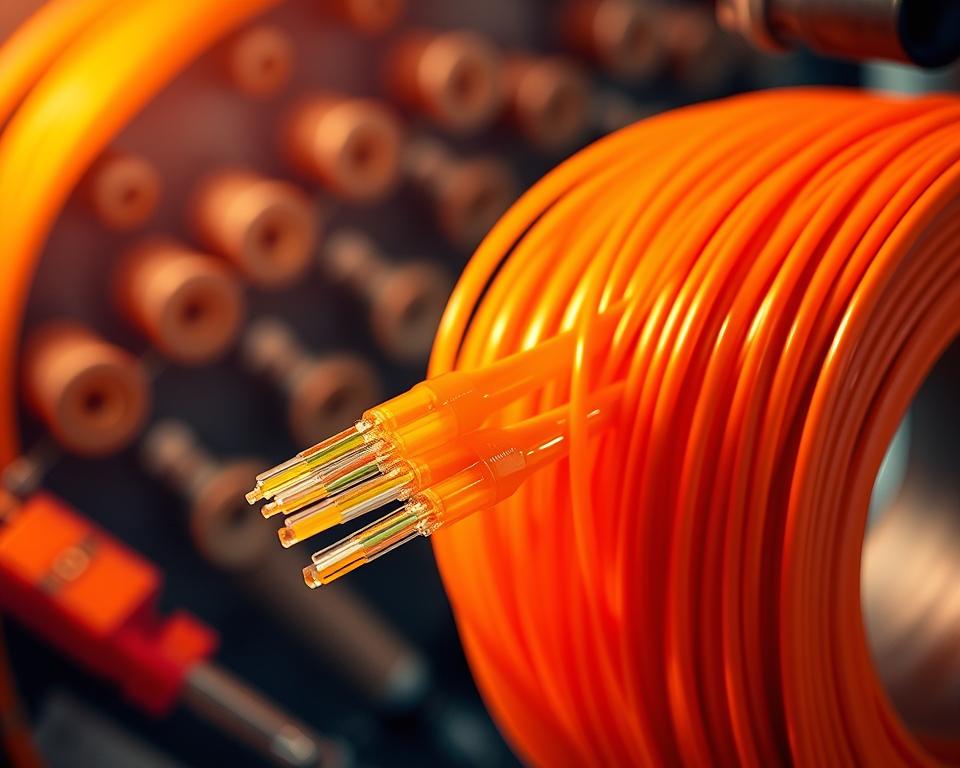

Fiber-To-The-Home Wire Manufacturing Line – Cutting-edge Production System

Have you realized that contemporary fiber optic wire networks are capable of running at rates of up to 190 m/min? This incredible efficiency stems from innovative production methods engineered for high-speed manufacturing.

Such setups are constructed to manage various wire variants, such as drop cables and firmly insulated cables. Their space-saving construction, commonly less than twenty-six meters, makes them ideal for modern facilities.

Seamless coupling with automated manufacturing systems guarantees smooth performance. Via MES/ERP connectivity, these fiber secondary coating line fabrication lines offer peerless accuracy and productivity. This renders them the leading option for businesses seeking to lead in the fiber network field.

Introduction to FTTH Cable Production Line

Productive production systems are key to meeting the growing need for reliable connectivity. These configurations are engineered to produce premium fiber optic cables that drive modern networks. Utilizing sophisticated techniques, they ensure accuracy and swiftness in each phase of the manufacturing process.

Understanding the FTTH Manufacturing Line

This fiber-to-the-home production system constitutes a consolidated process for fabricating FTTH drop cables. Such cables are made up of uncoated strands strengthened by iron or FRP materials, combined with protective sheathing. Consequently, it forms a robust and effective system for high-speed internet connections.

It supports diverse materials, such as PVC, LSZH, and PE plastics. This flexibility ensures it can meet diverse industry needs. Moreover, the quad-head fiber payout mechanism provides precise tension control, keeping stability within ±0.05N.

Reasons to Select Our Cutting-edge Production System

Our machinery excels for its exactness and productivity. Consider these highlights:

- Manages various wire sizes such as 2.0×3.0mm and 2.0×5.0mm drop cables

- Works with LSZH, PVC, and PE covering substances for adaptable uses

- Features a 4-head fiber pay-off system with tension control ranging from 0.4N to 1.5N

- Provides throughput up to 9km/h specifically for 2.0×3.0mm cables

With these features, our machine ensures smooth operations and high-quality output. This makes it the perfect choice for companies aiming to stay ahead in the fiber optic industry.

Key Features of Our FTTH Cable Production Line

State-of-the-art fabrication lines are reshaping the process by which optical fibers are manufactured. Our high-tech system merges exactness, performance, and modern advancements to produce premium performance. Below, we explore the standout features that make our system a leader in the industry.

Precision Extruder and Adjustment Head

Fundamental to our operation is a dedicated 50mm extruder engineered for exact substance allocation. It secures steady standards in all cables manufactured. The free adjustment head allows for seamless customization, accommodating different substances like PVC, LSZH, and PE plastics.

Using OMRON thermal regulation, the system maintains an accuracy of ±1°C. This level of precision guarantees optimal performance and reduces waste, rendering it an economical choice for production.

Motorized Fiber Release and Tension Control

Our motorized fiber release system is engineered to maintain tension between 0.4N and 1.2N. It guarantees gentle fiber management and curbs potential damage while manufacturing. The dual-wheel capstan system, with diameters of 640mm and 400mm, further enhances stability and control.

Such a trait significantly aids in crafting superior optical cables, as it ensures consistent tension throughout the process.

Automated Take-Up and Line-Receiving System

Our dual-shaft take-up system supports reels ranging from PN400 to PN630, providing adaptability for assorted manufacturing requirements. Its self-operating reel collection removes manual intervention, saving time and reducing labor costs.

In addition, the X-shaped laser gauge delivers instantaneous inspection of cable dimensions, confirming that each optical cable adheres to rigorous benchmarks, resulting in trustworthy and long-lasting outputs.

State-of-the-art Technology Powering the Production Process

Cutting-edge technology is reshaping the fiber optic manufacturing process. Our equipment is engineered to provide exactness, consistency, and productivity, to achieve optimal outcomes on all orders. Outlined below are the breakthrough characteristics that distinguish our apparatus.

International Industrial Computer Control System

Central to our operation lies the FiberCAN PLC coupled with an industrial-grade PC interface. This technology ensures seamless operations and real-time monitoring. It allows for precise adjustments, enhancing the quality of every optical cable produced.

Operating at a mere 35KW/h under standard conditions, this system is power-saving. This reduces operational costs while maintaining high performance. A 9-meter cable accumulator supports continuous operation, cutting delays and boosting throughput.

High Stability and Reliability with Famous Brand Components

Our system incorporates premium components from renowned brands like OMRON controllers and international motors chosen for their durability and precision, ensuring long-term reliability.

The steel wire reinforcement and advanced FTTH cable production line handling mechanisms provide added strength and stability, guaranteeing that every manufactured cable attains superior industry benchmarks.

Integration with MES and ERP Systems

Our machinery connects effortlessly with MES and ERP software, facilitating instantaneous production oversight. Such integration secures openness and streamlined functionality during production.

With this integration, businesses can monitor production metrics, optimize workflows, and reduce waste, rendering it a savvy option for today’s industrial plants.

| Aspect | Benefit |

|---|---|

| FiberCAN PLC Control System | Precise adjustments and real-time monitoring |

| Low Energy Consumption of 35KW/h | Energy-efficient operations |

| 9-meter Reel Accumulator | Seamless operation |

| OMRON Controllers | Reliable and exact performance |

| ERP Integration | Live process supervision |

Uses of the FTTH Manufacturing System

Advanced production setups are transforming the way we create reliable fiber optic solutions. They are engineered to fulfill varied commercial requirements, offering flexibility and precision in every application. The following outlines the primary applications of this state-of-the-art system.

Manufacturing Home Drop Cables

This production line is outstanding at creating drop cables vital for rapid internet connectivity. It manages support wires from ø0.4 to ø1.0 to guarantee robust performance. The central bore, measuring ø56, ensures smooth interfacing with PN400 reel systems.

Key features include:

- Fiber-reinforced polymer with minor steel wire dispensing for extra support

- Portable die backing for rapid setup modifications

- Compatibility with both indoor and outdoor specifications

Manufacturing Tight Buffered and Loose Tube Cables

It proves perfect for manufacturing both closely buffered as well as loose tube cabling systems. Boasting a minimal attenuation of only 0.02dB/km, these cables perform remarkably well. The stranding process ensures precision, while the ability to handle ø1.2mm steel wires adds strength and reliability.

Adaptable Manufacturing for Different Cable Varieties

Adaptability is a defining feature of our production line. It supports a wide range of materials and configurations, making it suitable for diverse applications. Whether you need indoor or outdoor cables, our equipment delivers consistent quality and efficiency. Such flexibility permits meeting particular demands while maintaining superior output.

Advantages of Our FTTH Manufacturing System

Choosing state-of-the-art production solutions yields numerous benefits to fiber optic businesses. These systems are designed to optimize operations, reduce costs, and deliver high-quality products. Here are the principal merits that render our equipment indispensable for today’s production facilities.

Enhanced Efficiency and Productivity

Our system ensures fiber ribbone line high-speed operations, achieving outputs of 7-9km/h depending on the cable size, enabling companies to satisfy rising requirements while preserving excellence. The automated line-receiving feature further reduces manual labor, saving time and resources.

Cost-Effective Fiber Optic Installation

Its efficient use of 35KW/h power curtails energy expenses. The ergonomic design, featuring a 1000mm working height, enhances operator comfort and efficiency.

Consistent and Uniform Cable Finishing

Exact molding delivers a sleek and consistent exterior on all fiber products, minimizing additional loss to ≤0.02dB/km, ensuring top performance. Incorporating steel reinforcement further solidifies the cables, adapting them to diverse applications.

| Feature | Benefit |

|---|---|

| Rapid Throughput | Increased operational efficiency |

| 35KW/h Energy Consumption | Cost savings |

| Negligible Attenuation | Enhanced signal quality |

| 1000mm Working Height | User-friendly setup |

Conclusion

Advanced fiber optic manufacturing systems are setting new standards in the industry. With precision engineering and smart integration, these machines deliver unmatched reliability and efficiency. Their high-speed capabilities, reaching up to 190 meters per minute, ensure a strong return on investment for businesses.

They are complemented by expert technical assistance and tailored configuration choices to suit your requirements. Whether increasing capacity or improving product integrity, our technology ensures you maintain a competitive edge.

Ready to transform your manufacturing process? Reach out now to discover customized options that match your needs. Step into the future of optical cable production with our market-leading equipment.